Electronic leak detection is an accurate and efficient method that takes the guessing out of identifying even the trickiest roof leaks. In the Pacific Northwest, where relentless rain and damp conditions are a constant challenge, a building’s envelope’s integrity is tested year-round.

Water intrusion isn’t just a minor inconvenience—it can lead to significant structural damage, costly repairs, and potential safety hazards if left unaddressed. Electronic leak detection (ELD) is a solution designed to pinpoint even the smallest breaches with precision.

In this blog post, we’ll explore how electronic leak detection works, its benefits, and how it stands out as a game-changer for protecting buildings against water damage in our rainy climate.

Comparing Traditional and Modern Leak Detection Methods

Leak detection is a critical step in maintaining the health and safety of any building. Traditional leak detection methods include:

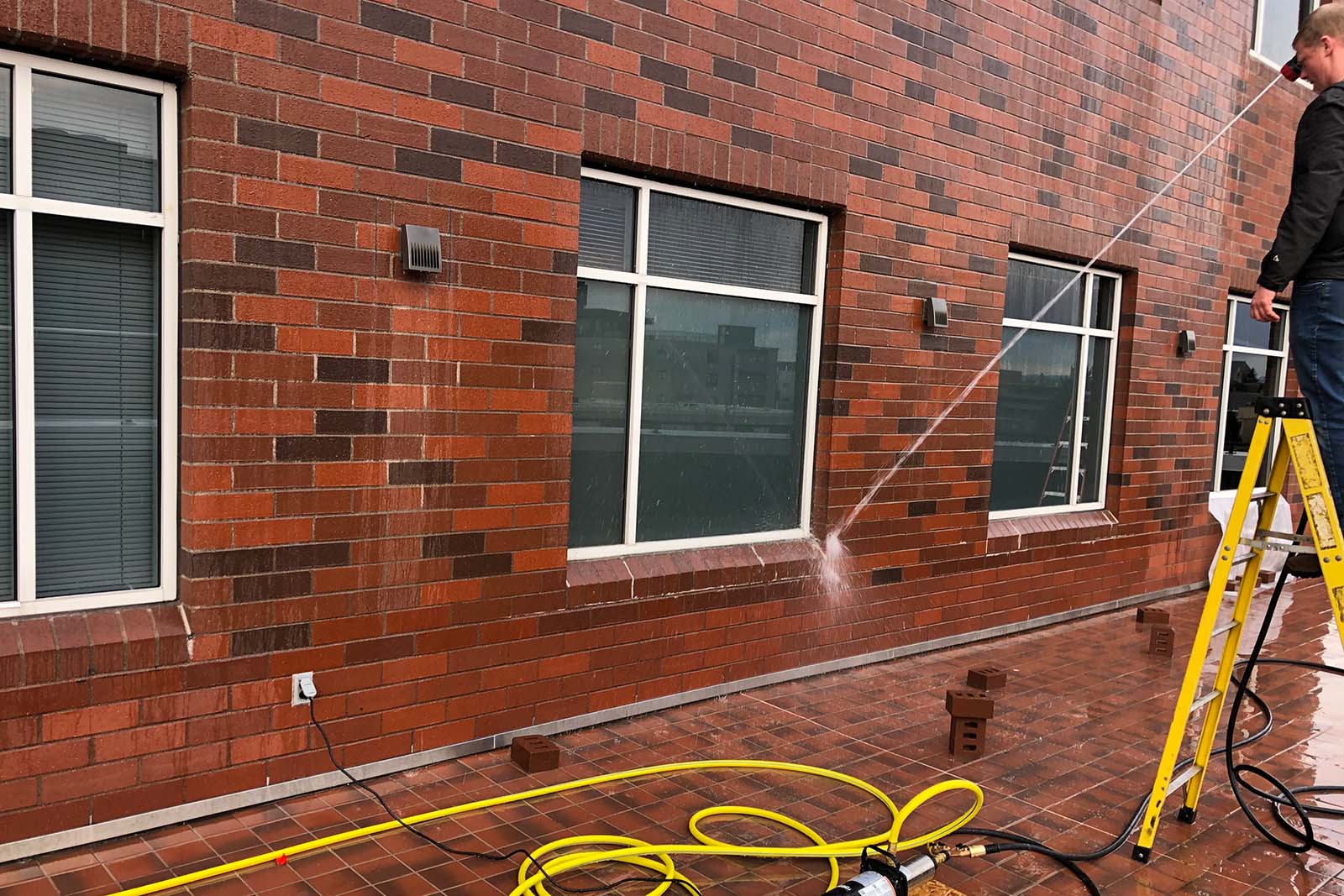

- Water testing with dye: This involves applying eco-friendly, biodegradable dyes of varying colors to different areas, allowing technicians to identify leaks based on where the dye seeps through.

- Visual inspection: Trained professionals search for signs of water damage, such as degraded materials, damp spots, peeling paint, or discoloration.

These methods are straightforward and cost-effective. However, they rely heavily on visible clues, which can limit their accuracy, especially for hidden or microscopic leaks.

Modern technologies have expanded the tools available for leak detection. More advanced methods of leak detection include:

- Thermal imaging: Heat-sensitive cameras—often mounted on drones—detect temperature differences that may indicate leaks. This method is particularly useful for surveying large or hard-to-reach areas, though it requires specialized expertise to interpret the results accurately. Thermal imaging alone, however, isn’t ideal for pinpointing the exact location of smaller breaches.

- Electronic leak detection: Among the most precise methods, ELD leverages electrical conductivity to identify even the tiniest openings. A low-voltage current is passed over a wet surface, and any breaches complete the circuit, alerting the technician. This method is fast, accurate, and can detect issues invisible to the eye.

How Electronic Leak Detection Pinpoints Breaches

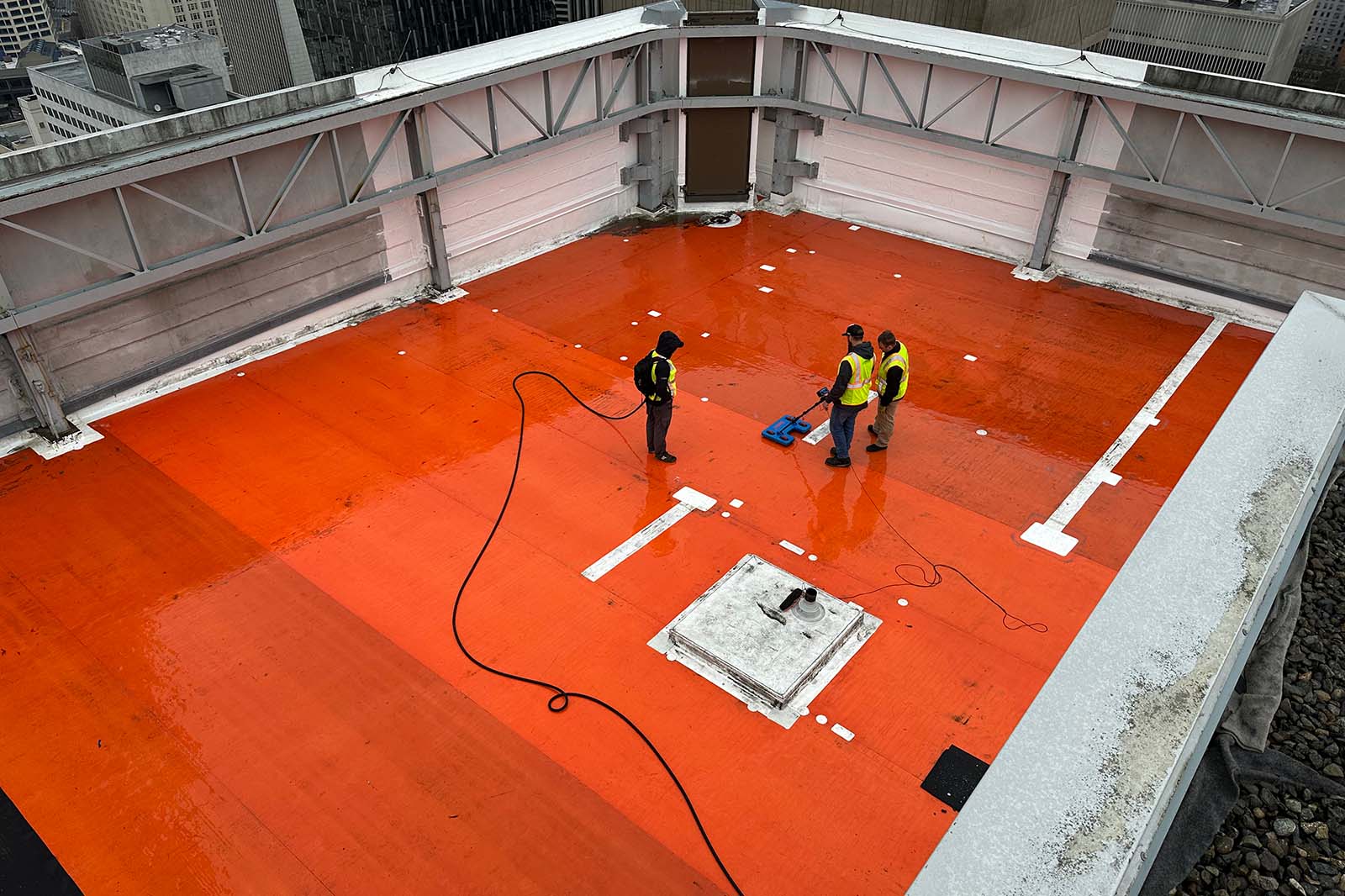

Electronic leak detection operates by utilizing the principles of electrical conductivity to identify breaches in a building’s waterproof membrane. The process begins with a trained technician using a hand-operated device resembling a vacuum cleaner. This device is connected to a low-voltage power source that emits an electrical current.

For the system to work, the surface under inspection must be damp or wet, as water is a conductive medium that facilitates the detection process.

The key to ELD’s precision lies in how the electrical circuit is completed. The conductive material beneath the waterproof membrane, such as steel or concrete, acts as the base layer for this circuit. When the technician moves the device across the surface, the current flows uniformly unless it encounters a breach.

If a leak is present, water penetrating through the breach connects the top surface to the conductive substrate, completing the circuit. This triggers a signal in the equipment, alerting the technician to the exact location of the leak.

By systematically scanning the surface, technicians can map all breaches with a high degree of accuracy. This process is both efficient and thorough, ensuring that no defect, regardless of size, is overlooked.

The Benefits and Limitations of Electronic Leak Detection

Electronic leak detection offers numerous advantages and some limitations for identifying breaches in a building’s waterproof membrane.

Advantages:

- Unparalleled precision. ELD is capable of detecting even pinhole-sized leaks that might be invisible to the naked eye or missed by traditional methods.

- Efficient process. ELD requires fewer personnel and completes inspections in a fraction of the time compared to manual visual searches. This efficiency can translate into significant cost savings for building owners, as repairs can be focused specifically on identified problem areas.

Limitations:

- Requires conductive materials. The building must be made with concrete or steel beneath the waterproofing layer. This means ELD cannot be used on all building types or surfaces.

Case Study: Solving Persistent Leaks with ELD

A Downtown Seattle high-rise faced a persistent water intrusion problem that impacted one of its office spaces. Initial inspections using water testing with dyes and visual assessment identified multiple leaks in sealant joints, cracks, and areas with missing sealant. Repairs were promptly made, but when the next rain arrived, new leaks emerged.

Evolution Architecture introduced electronic leak detection (ELD) as part of their diagnostic process. To ensure a thorough investigation, the team removed the overburden, including insulation and rock ballast across a 2,500-square-foot section, exposing the waterproof membrane.

Using the ELD system, the technician systematically scanned the area, quickly pinpointing previously undetected breaches. Some leaks were as small as a pinhole—virtually impossible to locate through traditional methods or visual inspection alone. The ELD process, completed in just a few hours, saved days of manual labor and provided precise results.

With the locations of all leaks clearly identified, a roofing contractor was able to address each one effectively. Since the repairs were completed, the building has remained leak-free, giving both occupants and managers peace of mind.

Maximizing Results with Electronic Leak Detection

To ensure the best results from electronic leak detection (ELD), preparation is key. One critical step is exposing the roof membrane. This direct access eliminates uncertainty and ensures that even the smallest breaches are identified.

Consulting with a professional team, like Evolution Architecture, can help determine the most efficient area to uncover while minimizing disruption.

Combining ELD with other leak-detection methods can provide a more comprehensive assessment. Techniques such as water testing with dyes or thermal imaging are excellent complementary tools. For instance, dyes can help isolate initial problem areas, and thermal imaging can scan large surfaces quickly, while ELD delivers pinpoint accuracy.

Leveraging multiple methods ensures thorough diagnostics, leaving no potential issue unchecked. With proper preparation and a strategic approach, ELD can significantly enhance the accuracy and reliability of leak detection.